Polymers are lightweight, durable, and easily processed into fabricated parts, features that promoted polymers to become the most relevant class of engineering materials by volume. However, recycling polymers is a challenge that materials scientists have been researching for decades.

An alternate route toward a more sustainable polymer industry is to increase the service lifetime of polymers. An intriguing new concept is to impart the ability to “self-heal” from structural damage. Michael Bockstaller, professor of materials science and engineering at Carnegie Mellon University Materials Science and Engineering, in collaboration with Krzysztof Matyjaszewski, professor of chemistry, has discovered that the binding of copolymers on the surface of nanoparticles that are already used in industrial manufacturing provides an economic and scalable route toward self-healing polymers with increased strength and toughness.

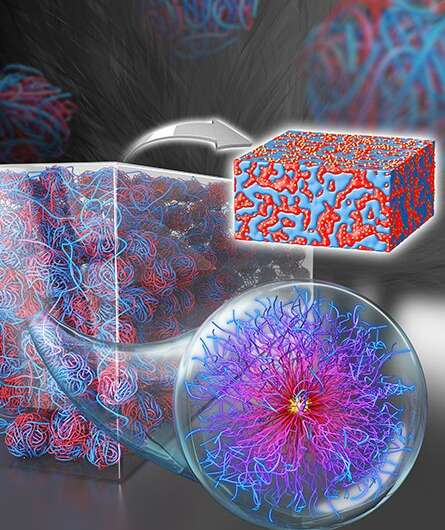

Normally when you think of the building blocks of materials, you think of atoms. In Bockstaller’s research group, this concept inspired a new approach to fabricate functional materials by assembling nanoparticle building blocks using a form of atom transfer radical polymerization, a technique invented and developed by Matyjaszewski. The properties of the resulting materials can be varied by controlling the interactions between nanoparticle building blocks. This concept opens up new possibilities to vary properties of engineering materials without having to change their chemical composition—a feature that is highly beneficial in the context of recyclability.

While working to make these particles more amenable to fabrication technologies like additive manufacturing, Bockstaller’s team experimented with putting copolymers at the surface of nanoparticles.

“If we can put polymers on the surface of nanoparticles, we can improve the interactions between them and make materials more mechanically robust and easier to form,” Bockstaller said.

Matyjaszewski added, “This work illustrates how controlling macromolecular architecture can dramatically enhance properties of various advanced materials.”

Copolymers are a special class of polymers that are made up of two different monomers and exhibit self-healing properties. The researchers found that when copolymers were added onto the surface of nanoparticles, new structures were formed that enhanced the polymer’s self-healing properties. This discovery is foundational to improving the recyclability of polymers.

“This enables us to avoid material failure,” Bockstaller explained. “If the material can self-heal, we reduce the need to discard materials damaged by stress.”

Bockstaller’s group will continue to explore strategies to maximize strength and toughness of copolymer-based self-healing materials and to make them available to scalable production methods.

This research was published in Macromolecules.

More information: Yuqi Zhao et al, Topologically Induced Heterogeneity in Gradient Copolymer Brush Particle Materials, Macromolecules (2022). DOI: 10.1021/acs.macromol.2c01131

Provided by Carnegie Mellon University Materials Science and Engineering