Could clothing monitor a person’s health in real time, because the clothing itself would be a self-powered sensor? A new material created through electrospinning, which is a process that draws out fibers using electricity, brings this possibility one step closer.

A team led by researchers at Penn State has developed a new fabrication approach that optimizes the internal structure of electrospun fibers to improve their performance in electronic applications. The team has published its findings in the Journal of Applied Physics.

This novel electrospinning approach could open the door to more efficient, flexible and scalable electronics for wearable sensors, health monitoring and sustainable energy harvesting, according to Guanchun Rui, a visiting postdoctoral student in the Department of Electrical Engineering and the Materials Research Institute and co-lead author of the study.

The material is based on poly(vinylidene fluoride-trifluoroethylene), or PVDF-TrFE, a lightweight, flexible polymer known for its ability to generate an electric charge when pressed or bent. That quality, called piezoelectricity, makes it a strong candidate for use in electronics that convert motion into energy or signals.

“PVDF-TrFE has strong ferroelectric, piezoelectric and pyroelectric properties,” Rui said, explaining that like piezoelectricity, pyroelectricity can generate electric charges when temperature change and thus influence the material. “It’s thermally stable, lightweight and flexible, which makes it ideal for things like wearable electronics and energy harvesters.”

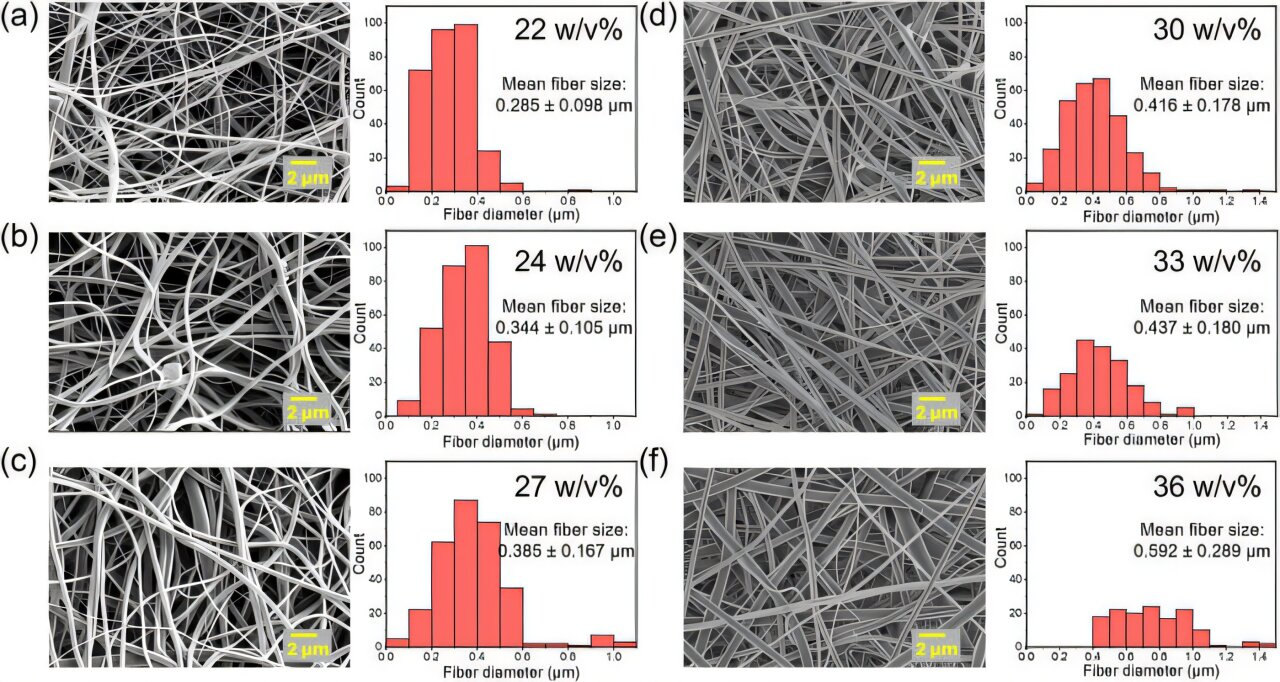

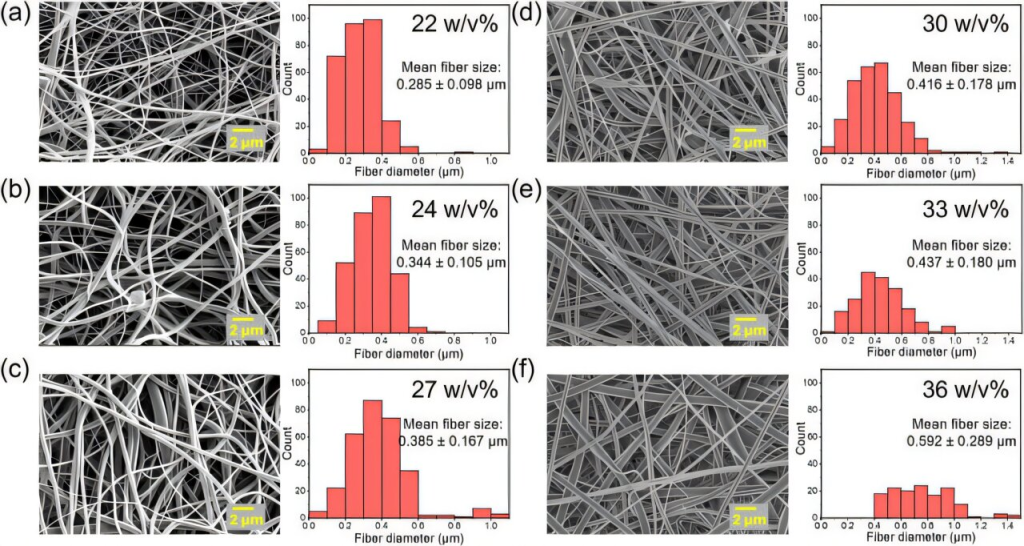

Electrospinning is a technique that uses electric force to stretch a polymer solution into extremely thin fibers. As the fibers dry, the way the polymer chains pack together determines their performance. The researchers hypothesized that altering the concentration and molecular weight of the polymer solution could lead to more organized molecular structures.

“Crystallinity means the molecules are more ordered,” Rui said, noting that the team also theorized the structure could have higher polar phase content. “And when we talk about polar phase content, we mean that the positive and negative charges in the molecules are aligned in specific directions. That alignment is what allows the material to generate electricity from motion.”

The researchers explained that electrospinning plays a key role in enabling this alignment.

“The process stretches the fibers in a highly mobile state, which predisposes the polymer chains to crystallize into the form we want,” said Patrick Mather, a co-author of the study and professor of chemical engineering and dean of the Schreyer Honors College. “You start with a liquid, and it dries over a split second as it travels to the collector. All the packing happens during that brief flight.”

One surprising discovery, Mather said, came from experimenting with unusually high concentrations of polymer in the solution.