A major stumbling block in our understanding of glass and glass phenomena is the elusive relationship between relaxation dynamics and glass structure. A team led by Dr. Qiaoshi Zeng from HPSTAR recently developed a new in situ high-pressure wide-angle X-ray photon correlation spectroscopy method to enable atomic-scale relaxation dynamics studies in metallic glass systems under extreme pressures. The study is published in Proceedings of the National Academy of Sciences (PNAS).

Metallic glasses (MGs), with many superior properties to both conventional metals and glasses, have been the focus of worldwide research. As thermodynamically metastable materials, like typical glasses, MGs spontaneously evolve into their more stable states all the time through various relaxation dynamic behaviors.

These relaxation behaviors have significant effects on the physical properties of MGs. Still, until now, scientists’ ability to deepen the understanding of glass relaxation dynamics and especially its relationships with atomic structures has been limited by the available techniques.

“Thanks to the recent improvements in synchrotron X-ray photon correlation spectroscopy (XPCS), measuring the collective particle motions of glassy samples with a high resolution and broad coverage in the time scale is possible, and thus, various microscopic dynamic processes otherwise inaccessible have been explored in glasses,” said Dr. Zeng.

“However, the change in atomic structures is subtle in previous relaxation process measurements, which makes it still difficult to probe the relationship between the structure and relaxation behavior. To overcome this problem, we decided to employ high pressure because it can effectively alternate the structure of various materials, including MG.”

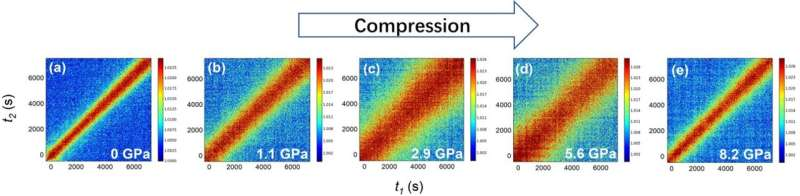

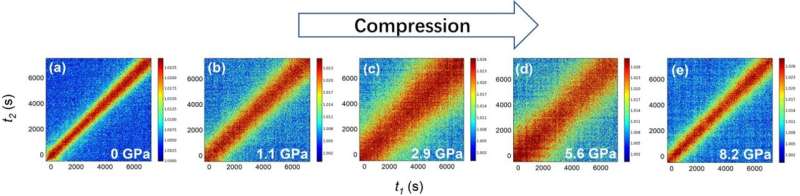

To this end, the team developed in situ high-pressure synchrotron wide-angle XPCS to probe a cerium-based MG material during compression. In situ high-pressure wide-angle XPCS revealed that the collective atomic motion initially slows down, as generally expected with increasing density. Then, counter-intuitively it accelerates with further compression, showing an unusual non-monotonic pressure-induced steady relaxation dynamics crossover at ~3 GPa.

Furthermore, by combining these results with in situ high-pressure synchrotron X-ray diffraction, the relaxation dynamics anomaly closely correlates with the dramatic changes in local atomic structures during compression, rather than monotonically scaling with either the sample density or overall stress level.

“With density increases, atoms in glasses generally get more difficult to move or diffuse, slowing down its relaxation dynamics. This is what we normally expect from hydrostatic compression,” Dr. Zeng explained.

“So the non-monotonic relaxation behavior observed here in the cerium-based MG under pressure is quite unusual, which indicates besides density, structural details could also play an important role in glass relaxation dynamics,” Dr. Zeng explained.

These findings demonstrate that there is a close relationship between glass relaxation dynamics and atomic structures in MGs. The technique Dr. Qiaoshi Zeng’s group developed here can also be extended to explore the relationship between relaxation dynamics and atomic structures in various glasses, especially those significantly tunable by compression, offering new opportunities for glass relaxation dynamics studies at extreme conditions.

More information: Qiaoshi Zeng et al, Pressure-induced nonmonotonic cross-over of steady relaxation dynamics in a metallic glass, Proceedings of the National Academy of Sciences (2023). DOI: 10.1073/pnas.230228112

Journal information: Proceedings of the National Academy of Sciences

Provided by Center for High Pressure Science & Technology Advanced Research