by Kristi L. Bumpus, Oak Ridge National Laboratory

Oak Ridge National Laboratory researchers have developed a method to simplify one step of radioisotope production—and it’s faster and safer.

ORNL produces several radionuclides from irradiated radium-226 targets, including actinium-227 and thorium-228, both used in cancer treatments. Continuously improving isotopes for human health is one of the lab’s missions.

Currently, it takes workers two weeks to prepare radium-226 targets for irradiation in the High Flux Isotope Reactor. The targets are exposed to radiation throughout the process, which involves pressing radium carbonate aluminum composite into 10 pellets—one each day—and sealing them into an aluminum capsule.

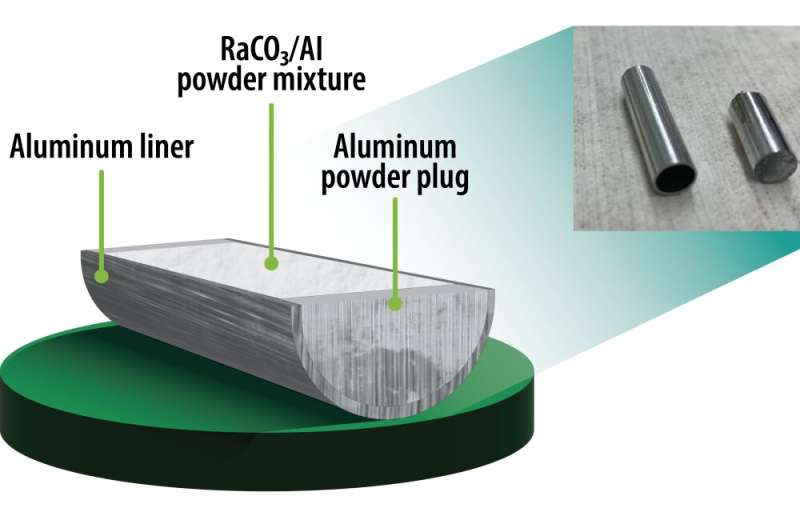

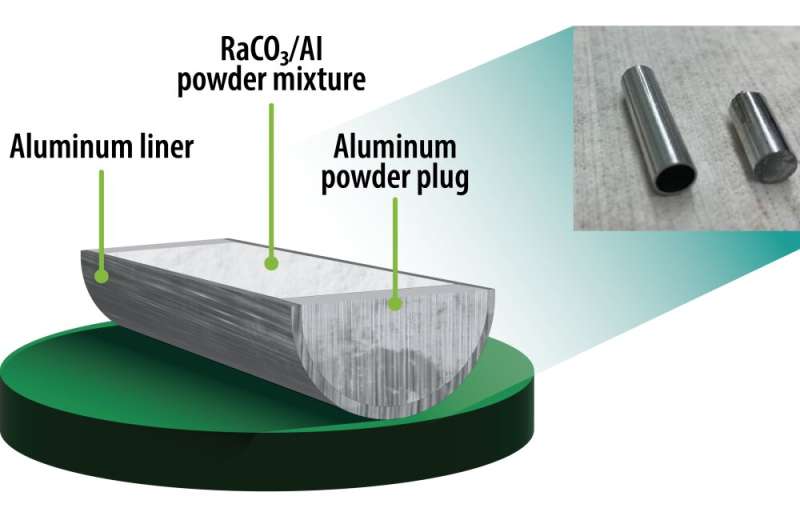

The new method uses a single, seamless aluminum liner with aluminum powder caps to press and seal the radium carbonate. This minimizes the time required to prepare targets, significantly decreasing radiation doses to workers, and also reduces the targets’ failure rate.

Provided by Oak Ridge National Laboratory