by International Journal of Extreme Manufacturing

![Various preparation techniques and characteristics for advanced powder metallurgy. (a) Mechanical alloying, (b) spark plasma sintering. Reproduced from [29]. CC BY 3.0. (c) Internal oxidation. Reprinted from [30], Copyright (2019), with permission from Elsevier.(d) In-situ processing. Credit: International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acdb0b How do ceramic particles strengthen metallic copper?](https://scx1.b-cdn.net/csz/news/800a/2023/how-do-ceramic-particl.jpg)

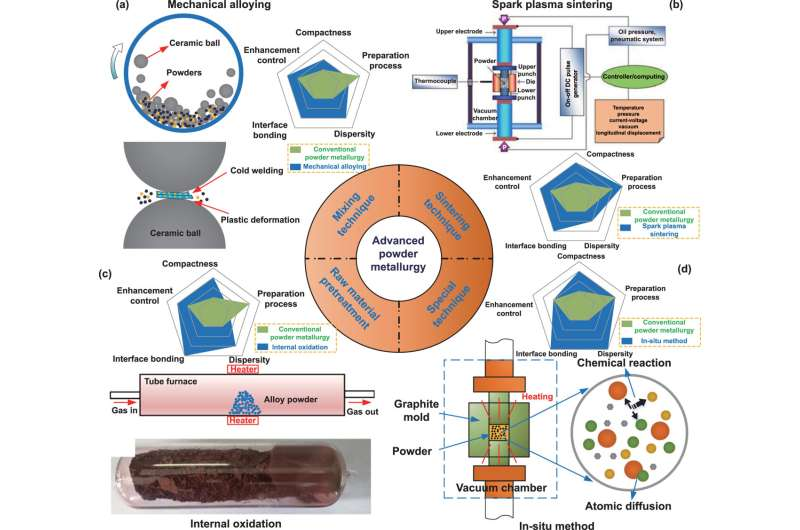

Publishing in the International Journal of Extreme Manufacturing, scientists from Jilin University and Edith Cowan University comprehensively reviewed the latest preparation techniques of copper matrix composites and the effect of ceramic particles on the mechanical properties, thermal conductivity and thermal expansion behavior of the composites. Four main aspects of particle characterization were included: particle content, particle size, particle morphology and interfacial bonding of particles to copper matrix.

Team leader, Feng Qiu, said, “By reviewing the preparation techniques and effect mechanisms of particle reinforced copper matrix composites, it is hoped that this will serve as a basis for more precise design and manipulation of composite microstructure to meet the growing demand for copper matrix composites in a wide range of application fields.”

So far, endeavors have been focusing on how to choose suitable ceramic components and fully exert the strengthening effect of ceramic particles in the copper matrix. Currently, the preparation of copper matrix composites by powder metallurgy is the most mature technique, but it still faces many unresolved process drawbacks.

Mechanical alloying and spark plasma sintering have a more prominent contribution to the improvement of grain refinement and densification of composite, as well as the dispersion of particles. While the internal oxidation and in-situ method could greatly enhance the interfacial bonding between the ceramic phase and the metal matrix. Further combinations of these advanced preparation techniques and the full utilization of each technical advantage remain to be explored in more detail.

The co-leading author, Prof. Hongyu Yang, added that, “practical challenges in manipulating particle characteristics reinforce the value of the preparation and mechanistic exploration, which contribute to further optimize the physical and chemical performance of composites.”

“Currently, the manipulation of ceramic particles in most copper matrix composites is mainly focused on particle content and size, while particle distribution, morphology, and interfacial bonding still need to be optimized, especially for the exploration of in-situ synthesis techniques.”

First author, Dr. Yifan Yan said, “Regarding the study of the effect mechanism of ceramic particle reinforced copper matrix composites, while experimental studies and mathematical models can reflect the influence of particle characteristics on material properties, finite element simulations provide a more intuitive perspective for predicting and studying the mechanism of intensifying action. However, optimal design of composites by computational simulation techniques in the definition of the constitutive model and the precise reconfiguration of the composite are largely unexplored.”

Prof. Laichang Zhang, an expert in advanced materials and also the co-leading author of the article, said, “Ongoing research in the field of ceramic reinforced copper matrix composites has yielded promising results in recent studies. Composites mixed with high-performance carbon nanotubes, carbon fibers, and advanced MAX-phase ceramic materials have demonstrated favorable comprehensive performance. However, there is limited information available on the interaction and distribution of strengthening phases.”

“Selecting and manipulating the strengthening phases in a rational manner could meet the performance requirements of copper matrix composites in various applications, but presents significant challenges in the design and preparation of composites. More complex material configuration designs, such as network structures and gradient structures, offer new opportunities to prepare anisotropic functional materials or speciality composites.”

More information: Yi-Fan Yan et al, Ceramic particles reinforced copper matrix composites manufactured by advanced powder metallurgy: preparation, performance, and mechanisms, International Journal of Extreme Manufacturing (2023). DOI: 10.1088/2631-7990/acdb0b

Provided by International Journal of Extreme Manufacturing