by Autonomous University of Barcelona

Researchers from the UAB and the ICN2 have developed an innovative material to fight against the spread of pathogens, infections and antimicrobial resistance. Inspired by the substances secreted by mussels to adhere to rocks, it can be used as a coating to protect health care fabrics and provides an effective alternative to commonly used materials such as paper, cotton, surgical masks and commercial plasters.

The research is published in the Chemical Engineering Journal.

The overuse of antibiotics has led to the development of antimicrobial resistance (AMR), a growing threat to public health worldwide. AMR occurs when bacteria change over time and no longer respond to drugs, antibiotics and other related antimicrobial medicines, making infections harder to treat and increasing the risk of pathogen spread, severe illness and death.

In fact, the World Health Organization (WHO) and United Nations (UN) have reported that AMR poses a major threat to human health around the world, probably overtaking cancer as the world’s leading cause of death by 2050.

In this scenario, the development of novel and more efficient antibacterial materials has become essential to reduce pathogen spread, thus preventing infections. Of relevance is the control of bacterial populations in health environments such as hospitals and other health care units to avoid the so-called nosocomial infections, mainly due to bacterial colonization on biomedical surfaces.

Today, this type of infection is the sixth leading cause of death in industrialized countries, and much higher in the developing world, specially affecting immunocompromised and intensive care patients (e.g., burns) and those with chronic pathologies such as diabetes.

Among the different materials that may spread bacterial populations, fabrics represent an integral part of patient care: From the clothes of doctors, surgeons and nurses to medical curtains, bed sheets, pillow coverings, masks, gloves, and bandages, which are directly in contact with sutures and wounds. For all these reasons, antibacterial coatings for medical fabrics have become a very active field of research.

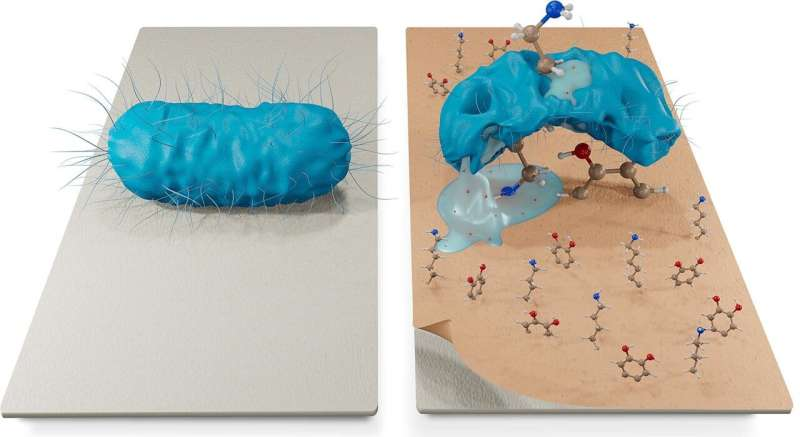

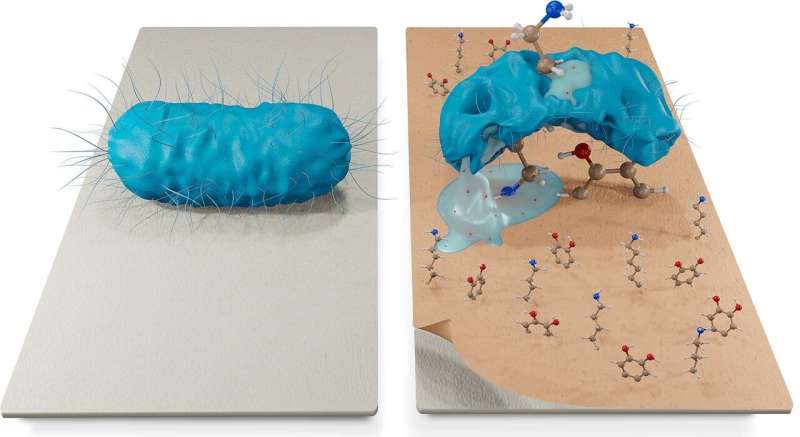

Researchers from the UAB Department of Biochemistry and Molecular Biology, the UAB Institute for Neuroscience (INc-UAB), and the Catalan Institute for Nanoscience and Nanotechnology (ICN2) have developed a family of biocompatible and bioinspired coatings produced by the co-polymerization between catechol derivatives and amino-terminal ligands.

Based on this, they have demonstrated that the use of these mussel-inspired coatings as efficient antimicrobial materials, based on their ability to evolve chemically over time in the presence of air and humid atmospheres, favoring the continuous formation of Reactive Oxygen Species (ROS). In fact, in addition to the formation of ROS, the synthetic methodology results in an excess of superficial free amino groups that induce the disruption of pathogen membranes.

“One of the main components found in the coatings (catechol and polyphenol derivatives) is found in the strands secreted by mussels, which are responsible for their adhesion to rocks under extreme conditions, under saline water,” explain UAB professor Victor Yuste and ICN2 researcher Salvio Suárez. “The fact that the coatings we have developed are inspired by this organism allows them to adhere to practically any type of surface and, in addition, are highly resistant to different environmental conditions such as humidity or the presence of fluids.

“In addition, natural compounds help to obtain more biodegradable, biocompatible materials with lower antimicrobial resistance compared to other bactericidal systems that end up generating resistance and, therefore, rapidly lose effectiveness.”

All of the commonly used sanitary equipment such as paper, cotton, surgical masks, and commercial plasters exhibited intrinsic multi-pathway antibacterial activity with rapid responses against a broad spectrum of microbial species. This included microorganisms that have developed resistance to extreme environmental conditions (such as B. subtilis), as well as pathogens considered the primary source responsible for many current infections, particularly those acquired in health care facilities.

These pathogens encompass multi-resistant microorganisms from both Gram-negative (E. coli and P. aeruginosa) and Gram-positive (S. aureus, methicillin-resistant S. aureus—MRSA and E. faecalis). These materials have also exhibited efficacy against fungi such as C. albicans and C. auris.

Moreover, its efficient application was demonstrated in wet atmospheres, as those found in health care environments, where respiratory droplets and/or other biofluids are present, thus reducing the risks of indirect contact transmission. Such antimicrobial activity was attributed to a direct contact killing process, where the pathogen is initially attached to the coating by catechol molecules and other polyphenol derivatives.

Then, a multi-pathway antibacterial effect is activated, mainly focused on a sustained generation of biosafety levels of ROS and electrostatic interactions with protic amino groups exposed to the surface. These antibacterial mechanisms induced a fast (180 minutes for bacteria and 24 hours for fungi) and efficient (more than 99%) response against pathogens, causing irreversible damage to the microorganisms.

These innovative coatings follow a simple one-step and scalable synthesis under mild conditions, using affordable materials and green chemistry-based methodologies. Moreover, the polyphenolic nature of their compositions and the absence of additional external antimicrobial agents enhance the simplicity of the bio-inspired coatings and avoid the induction of AMR and its cytotoxic effects on host cells and the environment.

Worth mentioning is that different parameters such as color, thickness and adhesion were fine-tuned, thus offering an adaptable solution for the different demands of the final material application. In general, the designed bio-inspired coatings have demonstrated a huge potential for further translation into clinics, as they represent a feasible alternative to existing antimicrobial materials.