by University of California – Riverside

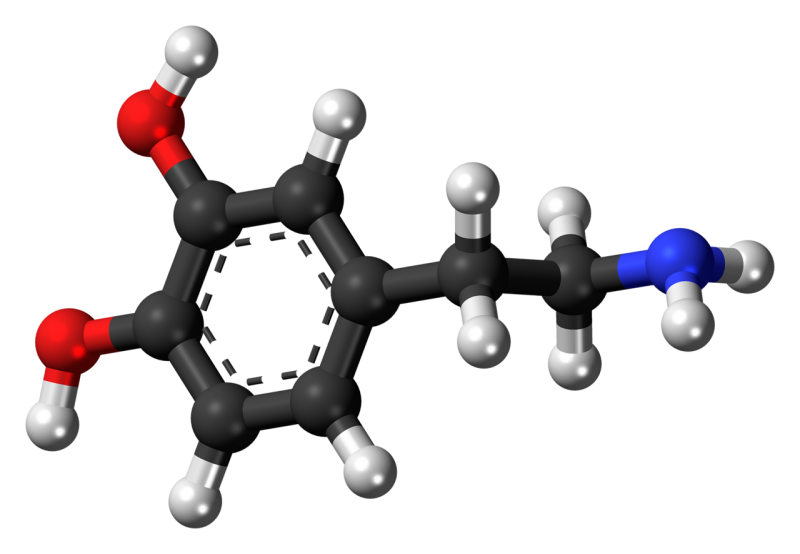

Some molecules exist in two forms, such that their structures and their mirror images are not superimposable, like our left and right hands. Called chirality, it is a property these molecules have due to their asymmetry. Chiral molecules tend to be optically active because of how they interact with light. Oftentimes, only one form of a chiral molecule exists in nature, for example, DNA. Interestingly, if a chiral molecule works well as a drug, its mirror image could be ineffective for therapy.

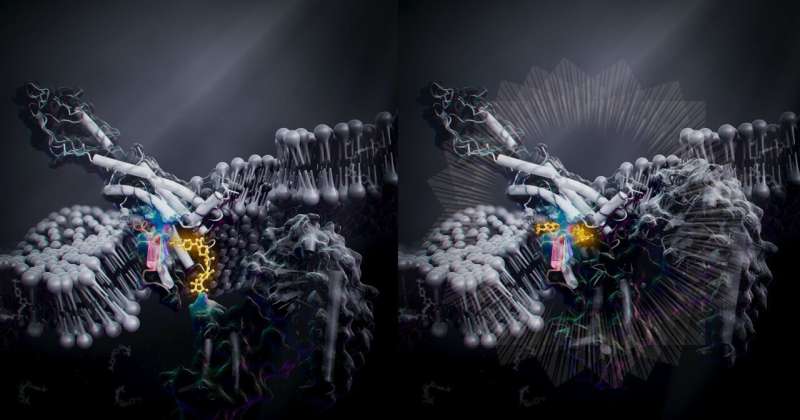

In trying to produce artificial chirality in the lab, a team led by chemists at the University of California, Riverside, has found that the distribution of a magnetic field is itself chiral. The research paper titled, “A magnetic assembly approach to chiral superstructures,” appears in the journal Science.

“We discovered that the magnetic field lines produced by any magnet, including a bar magnet, have chirality,” said Yadong Yin, a professor of chemistry, who led the team. “Further, we were also able to use the chiral distribution of the magnetic field to coax nanoparticles into forming chiral structures.”

Traditionally, researchers have used “templating” to create a chiral molecule. A chiral molecule is first used as the template. Achiral (or non-chiral) nanoparticles are then assembled on this template, allowing them to mimic the structure of the chiral molecule. The drawback to this technique is that it cannot be universally applied, being heavily dependent on the specific composition of the template molecule. Another shortcoming is the newly formed chiral structure cannot be easily positioned at a specific location on, say, an electronic device.

“But to gain an optical effect, you need a chiral molecule to occupy a particular place on the device,” Yin said. “Our technique overcomes these drawbacks. We are able to rapidly form chiral structures by magnetically assembling materials of any chemical composition at scales ranging from molecules to nano- and microstructures.”

Yin explained that his team’s method uses permanent magnets that consistently rotate in space to generate the chirality. He said transferring chirality to achiral molecules is done by doping, that is incorporating guest species, such as metals, polymers, semiconductors, and dyes into the magnetic nanoparticles used to induce chirality.

Yin said chiral materials acquire an optical effect when they interact with polarized light. In polarized light, light waves vibrate in a single plane, reducing the overall intensity of the light. As a result, polarized lenses in sunglasses cut glare to our eyes, while non-polarized lenses do not.

“If we change the magnetic field that produces a material’s chiral structure, we can change the chirality, which then creates different colors that can be observed through the polarized lenses,” Yin said. “This color change is instantaneous. Chirality can also be made to disappear instantaneously with our method, allowing for rapid chirality tuning.”

The findings could have applications in anti-counterfeit technology. A chiral pattern that signifies the authenticity of an object or document would be invisible to the naked eye but visible when seen through polarized lenses. Other applications of the findings are in sensing and the field of optoelectronics.

“More sophisticated optoelectronic devices can be made by taking advantage of the tunability of chirality that our method allows,” said Zhiwei Li, the first author of the paper and former graduate student in Yin’s lab. “Where sensing is concerned, our method can be used to rapidly detect chiral or achiral molecules linked to certain diseases, such as cancer and viral infections.”

Yin and Li were joined in the research by a team of graduate students in Yin’s lab, including Qingsong Fan, Zuyang Ye, Chaolumen Wu, and Zhongxiang Wang. Li is now a postdoctoral researcher at Northwestern University in Illinois.

More information: Zhiwei Li et al, A magnetic assembly approach to chiral superstructures, Science (2023). DOI: 10.1126/science.adg2657. www.science.org/doi/10.1126/science.adg2657

Journal information: Science

Provided by University of California – Riverside